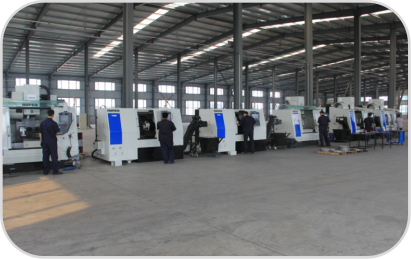

Automatic molding line in China

Japan Tokyu AMFⅢ-07L/R automatic molding line

As for the sand castings, there are several molding processes, which include manual moulding, machine molding (mechanical moulding), automatic machine molding. The automatic molding include horizontal molding and vertical molding. The famous brands include KW, disa, sinto, HWS, TOKYO, TOYO and luolamendi etc.

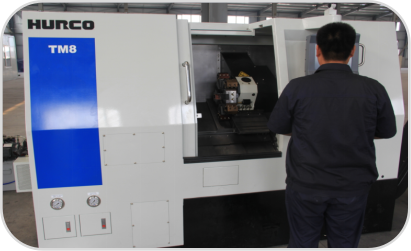

We import 4 sets of Japan Tokyo manufactured AMFⅢ-07L/R automolding lines, and 2 sets of AMFⅢ-08L/R automolding lines.

Automatic molding line usually produces small to medium castings with weights from 0.5kg to 50kg. This line uses green sand as the sand material. They can use the oil sand core and precoated sand core.

What is the advantage of the auto molding line?

Firstly, high production efficiency.

Secondly, good surface quality and dimensions.

However, there are also some disadvantages for the auto molding line. The auto molding line needs metal patterns / molds. The metal patterns usually cost from 2000 USD to 4000 USD. Therefore, if your annual demand is small, we do not suggest you to use auto molding line. Secondly, they have size and weight limitation.

Thirdly, since the cooling time is short, the castings will have some level of deformation during cooling. Therefore, if the figure or structure of the castings are easy for deformation, you can not make them by auto molding line.

Fourthly, the sand cleaning is through the violent vibration. Therefore, the strong shake will damage the small buttons on the surface of castings. The castings will also damage each other during sand cleaning period.

So we think, the automatic molding can not completely replace the traditional manual molding process. These molding processes can be a good supplement to each other.