Application of cast iron part

Cast iron is made by re-melting pig iron, often along with substantial quantities of iron, steel, limestone, carbon (coke) and taking various steps to remove undesirable contaminants. Phosphorus and sulfur may be burnt out of the molten iron, but this also burns out the carbon, which must be replaced. Depending on the application, carbon and silicon content are adjusted to the desired levels, which may be anywhere from 2–3.5% and 1–3%, respectively. Other elements are then added to the melt before the final form is produced by casting.

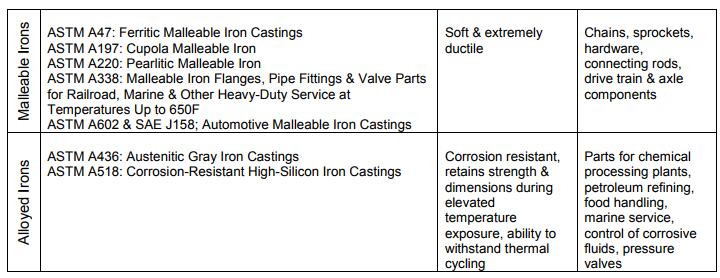

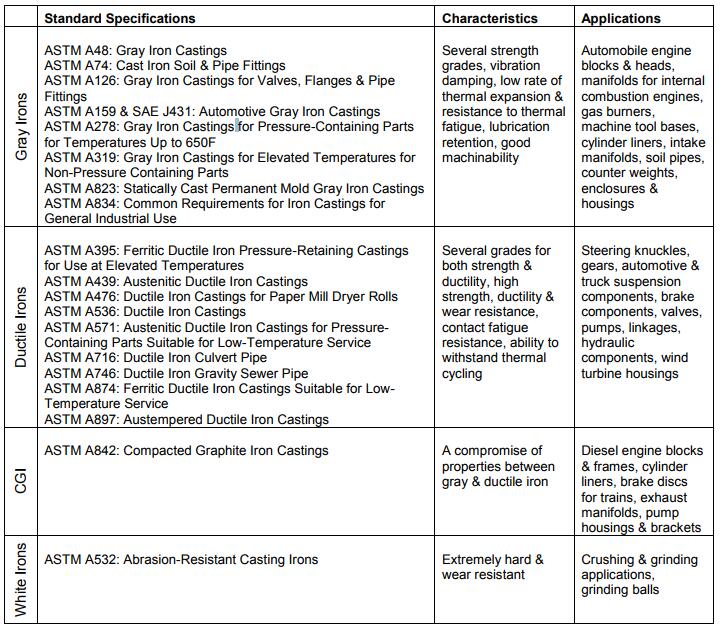

Specifications, Characteristics and Typical Applications:

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

Message