Application of cast iron

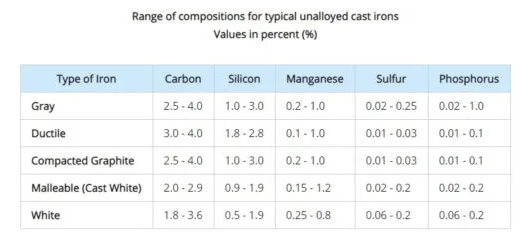

Important types of cast iron:

Grey

Ductile

Compacted graphite

White

Malleable

Abrasion resistant

Nodular or spheroidal

Austenitic

Now let's discuss properties of each of them briefly.

White cast iron

Carbon is present here in the form of Iron carbide (Fe3C).

Its properties are

It has High compressive strength

It is difficult to machine

It has Good hardness

It has Resistance to wear

Gray cast iron

Carbon here is mainly in the form of graphite. It is inexpensive.

Its properties are

It has Good machinability

It has Good resistance to galling and wear

It has high compressive strength

It is brittle

Its properties are

It has High ductility

It has High strength

Malleable cast iron

They are made malleable with the help of annealing. They are used to make parts where forging is expensive like, brake supports, hubs of wagon wheels etc. They are in expensive.

Its properties are

They have High ductility

They are tougher than gray cast iron

They can be twisted or bent without fracture

They have excellent machining capabilities

5. Nodular or spheroidal cast iron

Here graphite is present in the form of spheres or nodules.

Its properties are

They have high tensile strength

They have good elongation properties

Advantages of cast iron

It has Good casting properties

It is available in large quantities, hence produced in mass scale. Tools required for casting process are relatively cheap and inexpensive. This results into low cost of its products.

It can be given any complex shape and size without using costly machining

It has three to five times more compression strength compared to steel

It has Good machinability (gray cast iron)

It has excellent anti-vibration (or damping) properties hence it is used to make machine frames

It has good Sensibility

It has excellent resistance to wear

It has constant Mechanical properties between 20 to 350 degree Celsius

It has very low notch sensitivity

It has Low stress concentration

It bears Low cost

It has Durability

It has Resistance to deformation

Disadvantages of cast iron

It is Prone to rusting

It has poor tensile strength

Its parts are section sensitive, this is due to slow cooling of thick sections.

failure of Its parts is sudden and total, it does not exhibit yield point.

It has poor impact resistance

Compared to steel it has poor machinability

It has High weight to strength ratio

It has High brittleness

It is Non machinable (white cast iron)

Applications of iron castings:

It is used in making following parts

It is used in making tractor parts, agricultural parts

It is used in making different machine parts

It is used in making automotive parts

It is used in making valve parts and pump parts

It is used in making marine parts.

It is used in making any kind of customized shape metal parts